I Have a Garage, But Not Much Else

In a previous note I described my reasons for buying TC4985. The car was (and still is) intended to be driven, but also something with which I can tinker. I like the word ‘tinker’. It seems to imply a degree of experimentation and not really following the rules. With most things I do tend to treat the instructions as something to which you refer as a last resort. However, with the TC, as we shall see later, I tend to take a different approach.

Whatever you want or need to do on your car does require a certain level of supporting environment. Unlike some people, I do not have an insulated and heated garage, but it is just big enough to hold the TC and our small day-to-day car, with cupboards and shelves down one side and a bench and a fridge at the back. Doesn’t every well equipped garage have a fridge? Well, I would hardly call my garage well equipped, but the fridge does come in handy at those times of the year when we have lots of visitors. Anyway, my garage has six glass doors, each hinged together, that slide around one side wall. Although I can’t use that wall to store anything, I have several structures hanging from the rafters, holding assorted oddments that are infrequently used or just might come in handy one day. They are also handy for suspending two pieces of string that help when positioning the cars next to each other. Luckily, garden tools and equipment are stored in two sheds.

Needless to say I don’t have a pit in the garage. So if I need to get under the car I have to put it on axle stands. A trolley jack that I’ve had since I ran a Mk1 Triumph Spitfire and a Morris 1000 Traveller some 35 years ago, helps me put the car on the stands. One problem that I have is that the concrete floor is not very smooth, so the jack does not easily roll as the car goes up (or down). However, as you can see in the photo, space to get under the car is still limited. Since my nearest focal point has moved away a little in recent years, I need to wear reading glasses whilst under the car!

Needless to say I don’t have a pit in the garage. So if I need to get under the car I have to put it on axle stands. A trolley jack that I’ve had since I ran a Mk1 Triumph Spitfire and a Morris 1000 Traveller some 35 years ago, helps me put the car on the stands. One problem that I have is that the concrete floor is not very smooth, so the jack does not easily roll as the car goes up (or down). However, as you can see in the photo, space to get under the car is still limited. Since my nearest focal point has moved away a little in recent years, I need to wear reading glasses whilst under the car!

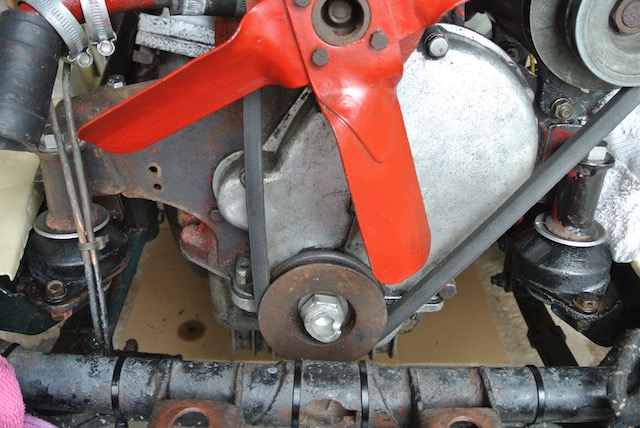

Another group of items that are needed in my ‘support environment’ is tools. I’ve mentioned the trolly jack, axle stands and my bench (built from wood that I rescued from a building site nearly 40 years ago) and I also have an engineer’s vice that I was given. However, the rest of my tools are a motley set of open-ended spanners, socket sets and box spanners, most of which are AF type. Of course, the TC mechanicals use all Whitworth (BSW) nuts and bolts. Although the XPAG engine uses an obscure French metric thread, the head sizes are also BSW/BSF. Some AF spanners fit BSW nuts and I have a few small Whitworth spanners. In fact I was able to remove the radiator without expanding my tool kit. I had noticed that the bottom bracket holding the radiator to the chassis was rusty, so I removed the bonnet, radiator shell and radiator. Removed the bracket from the radiator (which required unsoldering some joints), de-rusted it and painted it (I probably should have bought a new one) and replaced the rubber fittings. The photo shows the front of the car with the radiator removed, but after I had replaced the engine mounts. The rubber parts of these were quite cracked, so it was sensible to replace them while I had easy access. Lifting the engine slightly using one of the three bottle jacks that I have acquired over the years was enough to take the strain off the mounts.

It wasn’t until I started to replace the handbrake cables (there is one down each side of the car) that I decided to buy a new set of Whitworth spanners, open at one end and a ring at the other. The spanners made the job much easier, but my biggest problem was information, or rather the lack of it. You would think that removing the old cables would provide enough details on how to fit the new ones. But the new cables had extra collets and washers and had a plastic covering to the spiral metal sheath (which stopped it fitting into a fixing point). The TC’s handbook describes the hydraulic brake system in great detail (as well as such things as how to decoke the cylinder head), but provides no details at all about the handbrake. All the restoration blogs that I have read again provide little detail. In fact the only information that I could find were drawings from a parts catalogue. However, this drawing has an extra plate and, being an ‘exploded’ view does not make it clear how they fit together. In the end it came down to examining each part and working out how they were designed to work and then to assemble the parts accordingly. The photo shows the lever end of one cable, with its connection to the lever cross-tube and the fixing of the outer sheath to the chassis.

It wasn’t until I started to replace the handbrake cables (there is one down each side of the car) that I decided to buy a new set of Whitworth spanners, open at one end and a ring at the other. The spanners made the job much easier, but my biggest problem was information, or rather the lack of it. You would think that removing the old cables would provide enough details on how to fit the new ones. But the new cables had extra collets and washers and had a plastic covering to the spiral metal sheath (which stopped it fitting into a fixing point). The TC’s handbook describes the hydraulic brake system in great detail (as well as such things as how to decoke the cylinder head), but provides no details at all about the handbrake. All the restoration blogs that I have read again provide little detail. In fact the only information that I could find were drawings from a parts catalogue. However, this drawing has an extra plate and, being an ‘exploded’ view does not make it clear how they fit together. In the end it came down to examining each part and working out how they were designed to work and then to assemble the parts accordingly. The photo shows the lever end of one cable, with its connection to the lever cross-tube and the fixing of the outer sheath to the chassis.

I said earlier that I am a ‘tinkerer’. However, when it comes to the TC I like to have a good idea of what I am going to do before I start. So I need to research available documentation. When it comes to information on a TC, the book ‘TCs Forever’ is often described as the ‘bible’ for restorers. I bought a TC that doesn’t need restoring, but it does need some work doing on it, and books and blogs that describe the restoration process, particularly those with plenty of photos, are a help when tackling any job. Now ‘TCs Forever’ is published in Australia (the author being Australian) and, although on at least its third printing, is only produced in small quantities. Consequently a new copy costs £96 plus £4 deliver! My wife said “You want to pay how much for a book?”, so I eventually found an ‘as new’ second-hand copy (that happens to be signed by the author), saving me a whole £10. The book gives a good description of the handbrake cable assembly and adjustment with good diagrams, but no photos. Having bought the book after replacing the cables I luckily find that I only have a small amount of re-adjustment to do when I next have the car on axle stands.

So my support environment is improving. I have space in the garage (when our other car is put outside) for working on the car, I have a (slightly) better selection of tools and my sources of information are expanding. Now, how does the Bishops Cam steering box work?

So my support environment is improving. I have space in the garage (when our other car is put outside) for working on the car, I have a (slightly) better selection of tools and my sources of information are expanding. Now, how does the Bishops Cam steering box work?

(Written 17th February 2016; published in WSMGOC Main Gear, April 2016.)

© David James 2020 Last updated: 9th April 2020